Cable Gland

Cable Gland

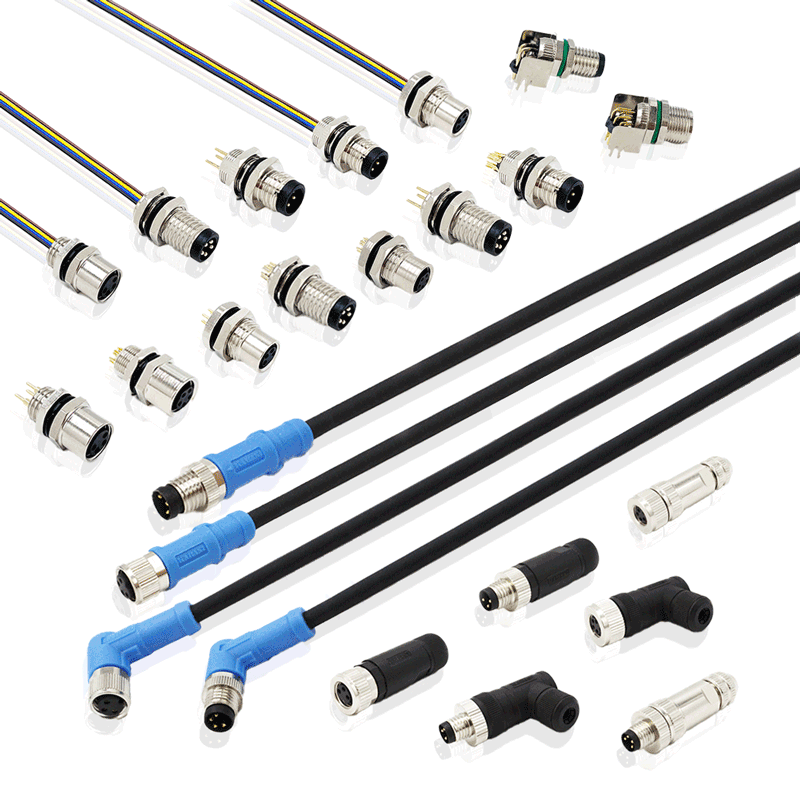

Cable gland is an essential component in electrical installations. It is a device used to secure and protect the ends of electrical cables. Cable glands are employed in various industries, including automotive, telecommunications, manufacturing, and construction.

Made of materials like brass, stainless steel, and plastic, cable glands are manufactured to withstand harsh environmental conditions. They are produced in various shapes and sizes to suit specific requirements. Their construction includes an outer body, a packing seal, and a locking mechanism.

The primary purpose of cable glands is to provide a seal around an electrical cable as it passes through a panel or enclosure. The gland prevents harmful elements such as dust, moisture, and unwanted gases from entering the electrical system. It also protects the cable from external damages like cuts and abrasions.

Cable glands also ensure that electrical connections are secure and stable. The locking mechanism of the gland holds the cable firmly in place without damaging the insulation or conductors. Cable glands ensure that there are no wire pullouts or electrical failures, which can lead to accidents or malfunctions.

The use of cable glands can also eliminate the need for additional protective devices such as cable ties, duct tapes, or cable trays. These devices add extra weight, bulk, and cost to the installation. Cable glands are cost-effective, easy to install, and require minimal maintenance.

In summary, cable glands are an essential component in electrical installations. They provide a secure, stable, and sealed connection between cables and enclosures, ensuring the safety and reliability of the electrical system. Cable glands are durable, versatile, and adaptable to various installation requirements. They have become an indispensable part of modern electrical applications and are continuously evolving to meet the demands of the industry.

FAQ

1. How do cable glands help maintain IP protection in industrial environments?

The engineering properties of special materials for cable glands in maintaining Ingress Protection (IP) ratings that are critical in industrial environments.

2. Can cable gland glands accommodate different cable diameters?

No. Cable gland diameters can be custom designed to accommodate a variety of cable diameters without compromising integrity.

3. do engineers need specific certifications when designing cable glands for use in hazardous locations?

No. Verifying that cable glands are certified for use in hazardous locations ensures compliance with industry safety standards.

4. How does Leaka Electrical Equipment incorporate advanced technology into its cable gland designs?

Gain insight into the technological innovations Leaka has integrated to demonstrate its commitment to staying at the forefront of connector design.

5. How do custom cable glands meet unique project requirements in complex industrial installations?

We welcome cable gland customisation to meet the specific needs of complex industrial installations.

6. What role does corrosion resistance play in cable gland connectors, especially in marine applications?

Cable gland connectors are able to resist corrosion and are suitable in marine applications.