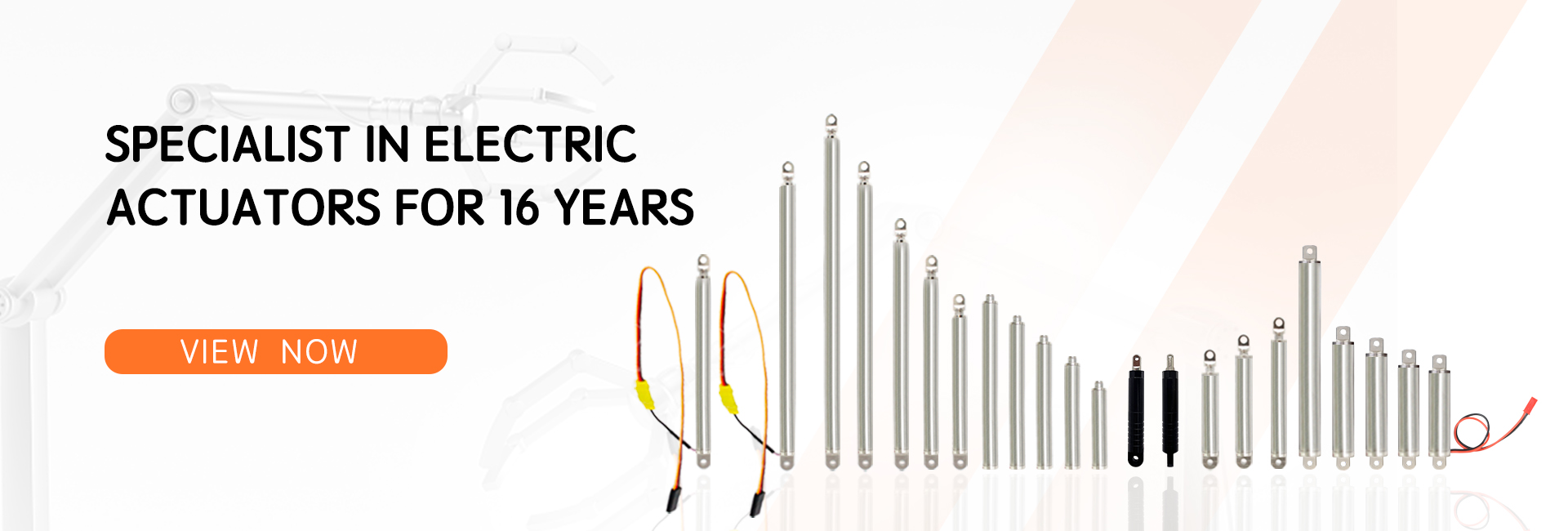

Electric Actuators

Electric Actuators

In the realm of motion control, electric actuators stand as a testament to innovation and efficiency. These devices have transformed the way mechanical motion is achieved across various industries, offering a plethora of advantages over traditional hydraulic and pneumatic actuators. From precise positioning to simplified control, electric actuators have become indispensable in modern automation systems.

Introduction to Mini Electric Actuators

Electric actuators are devices designed to convert electrical energy into mechanical motion. Unlike their hydraulic or pneumatic counterparts, electric actuators rely on electric motors to drive motion, offering precise control and flexibility in operation. These actuators come in various forms, including linear actuators, rotary actuators, and multi-axis systems, catering to diverse motion control requirements.

Materials Used in Micro Miniature Electric Actuators

The materials utilized in electric actuators play a crucial role in determining their performance, durability, and suitability for specific applications. Common materials employed in electric actuators include:

Aluminum: Aluminum is favored for its lightweight properties and corrosion resistance, making it an ideal choice for actuator casings and components where weight reduction is critical.

Steel: Steel is valued for its strength and durability, often used in load-bearing components of electric actuators to withstand high forces and ensure long-term reliability.

Plastics: Engineering plastics such as polyamide (PA) and polyoxymethylene (POM) find application in electric actuators for their low friction properties, chemical resistance, and suitability for intricate component designs.

Copper: Copper is utilized in electric actuators for its excellent electrical conductivity, essential for ensuring efficient power transmission within the actuator system.

Magnets: Permanent magnets, typically made of materials such as neodymium-iron-boron (NdFeB), are essential in electric actuators for generating magnetic fields necessary for motor operation.

Application of Electric Linear Actuators

Electric actuators find widespread application across various industries and sectors, owing to their versatility, precision, and ease of integration. Some common uses of electric actuators include:

Industrial Automation: Electric actuators are extensively used in industrial automation systems for tasks such as valve control, conveyor belt operation, and robotic arm movement. Their precise positioning capabilities and programmable control make them indispensable in modern manufacturing facilities.

Medical Equipment: In the field of medical equipment, electric actuators play a vital role in powering devices such as hospital beds, surgical tables, and diagnostic instruments. Their quiet operation, smooth motion, and compatibility with sensitive environments make them well-suited for medical applications.

Aerospace and Defense: Electric actuators are employed in aerospace and defense applications for functions such as aircraft wing flap control, missile guidance systems, and unmanned aerial vehicle (UAV) stabilization. Their lightweight construction, high precision, and reliability are essential in these critical systems.

Automotive: Within the automotive industry, electric actuators are utilized in various components including power windows, door locks, and adjustable seats. Their compact size, rapid response, and energy efficiency contribute to enhancing vehicle comfort and functionality.

Renewable Energy: Electric actuators play a significant role in renewable energy systems, particularly in solar tracking systems and wind turbine pitch control mechanisms. By precisely adjusting the orientation of solar panels and wind turbine blades, electric actuators optimize energy capture and maximize efficiency.

Advantages of Small Electric Actuators

Electric actuators offer several advantages over traditional hydraulic and pneumatic actuators, making them the preferred choice for many applications. Some key advantages include:

Precision: Electric actuators provide precise control over motion, allowing for accurate positioning and repeatability within micrometer or even nanometer ranges. This precision is essential in applications where accuracy is paramount, such as semiconductor manufacturing and laboratory automation.

Flexibility: Electric actuators offer greater flexibility in operation compared to hydraulic or pneumatic systems. They can be easily programmed and integrated into automated processes, allowing for dynamic motion profiles and on-the-fly adjustments to meet changing production requirements.

Energy Efficiency: Electric actuators are inherently more energy-efficient than hydraulic or pneumatic systems, as they only consume power when in operation. This energy efficiency translates to cost savings and reduced environmental impact, especially in applications with frequent or continuous motion.

Maintenance: Electric actuators require minimal maintenance compared to hydraulic or pneumatic systems, as they lack the complex fluid-based components prone to leakage and wear. This results in lower downtime, reduced maintenance costs, and increased system reliability over the long term.

Safety: Electric actuators offer enhanced safety features, such as overload protection and programmable limits, to prevent damage to equipment and ensure operator safety. These built-in safety mechanisms reduce the risk of accidents and downtime associated with mechanical failures.

Xiamen LEAKA Electrical Equipment Co., Ltd. is a company specializing in electric actuator research and development, production, once the introduction of micro-small self-developed actuators, access to the majority of model hobbyists, drone manufacturing, medical-related industry customers, electric actuators represent a paradigm shift in motion control technology, providing unparalleled precision, flexibility and efficiency in a wide range of applications. As materials, design and control technologies continue to advance, electric actuators will continue to drive innovation and advancements in automation, manufacturing and more. As industries increasingly adopt automation technologies and seek to optimize performance, electric actuators have become an indispensable tool in shaping the future of motion control.

Xiamen LEAKA Electrical Equipment Co., Ltd. is a company specializing in electric actuator research and development, production, once the introduction of micro-small self-developed actuators, access to the majority of model hobbyists, drone manufacturing, medical-related industry customers, electric actuators represent a paradigm shift in motion control technology, providing unparalleled precision, flexibility and efficiency in a wide range of applications. As materials, design and control technologies continue to advance, electric actuators will continue to drive innovation and advancements in automation, manufacturing and more. As industries increasingly adopt automation technologies and seek to optimize performance, electric actuators have become an indispensable tool in shaping the future of motion control.

1